Automated production

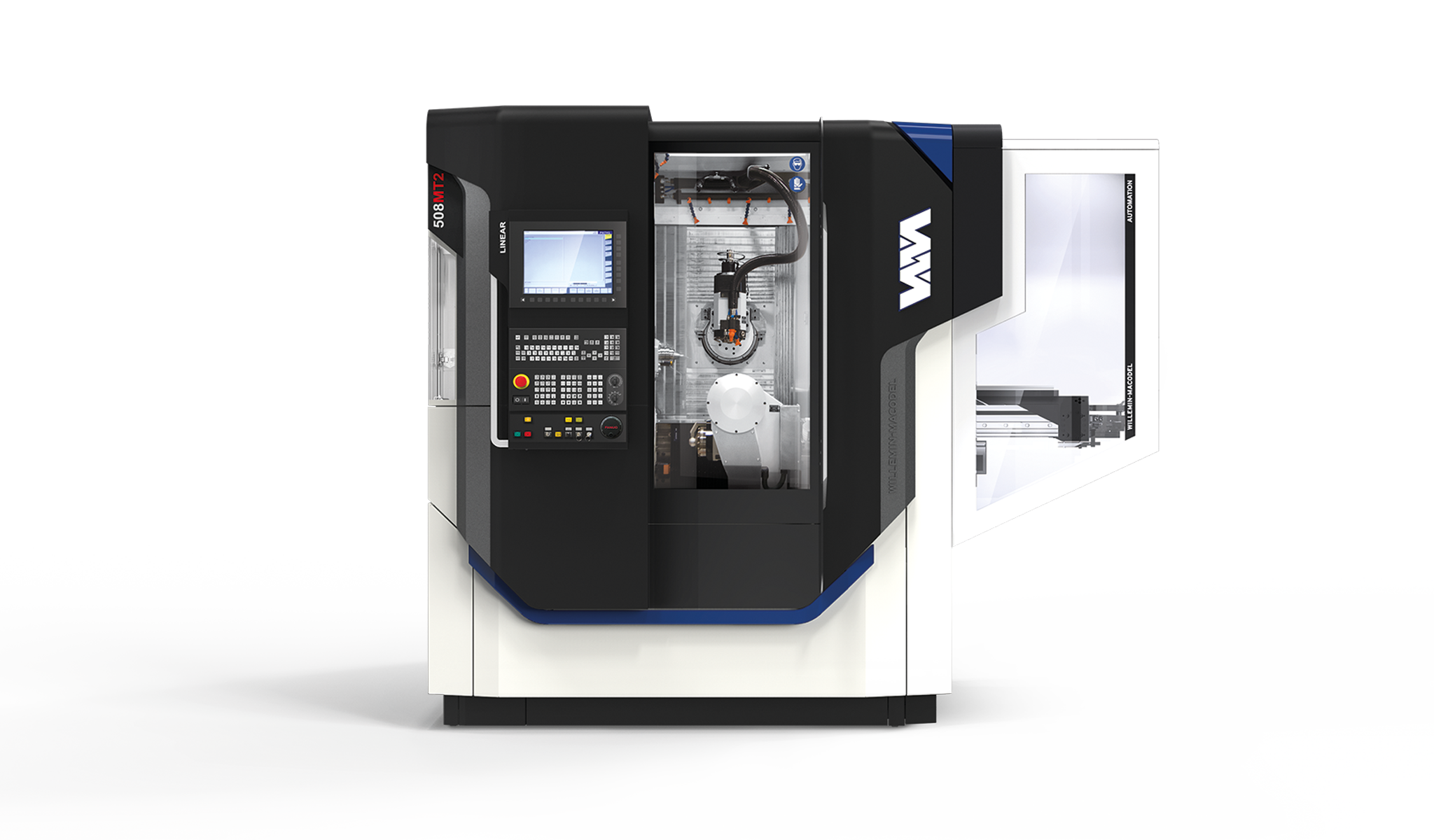

To increase autonomy, flexibility and production rate, Willemin-Macodel has developed a range of automation solutions from unloading of machined parts to multi-machine robotic cells.

The manipulator authorizes the loading and unloading of workpieces or pallets for small and medium part runs. It meets standard requirements without additional functions.

Robotic automation offers more possibilities: handling of pallets or fixtures, positioning and orientation of workpieces, cleaning and blowing of the workpiece and pallet set-down surface, and complete management of blanks, finished parts and scrap.

Willemin-Macodel automated robotic cells are available in various sizes with different degrees of complexity. They can be dedicated to a single machining center or integrated in a complete, flexible production cell which includes other processes in addition to machining (3D measurement of the machined part, monitoring, marking, etc.)

Automation at Willemin-Macodel

Benefiting from the latest technological developments and all of Willemin-Macodel’s expertise in high-precision machining, these flexible automation solutions can be adapted to our entire range of machines.

Manipulator / Poly-articuled robot

Manipulator

To increase the machine’s autonomy during machining, Willemin-Macodel offers a manipulator arm for loading and unloading workpieces or pallets. This economical manipulator comprises a pneumatic longitudinal axis with 2 fixed positions. 0 ° – 90 ° gripper optional.

508MT2 machine and manipulator dimensions

| Length | 2615 mm |

| Depth | 2405 mm |

Manipulator characteristics (508)

| Dimension (l x w x h) | 910 x 750 x 1500 mm |

| Arm travel | 900 mm |

| Load capacity | 40 kg |

| Storage area | 400 x 200 mm |

308S2 machine and manipulator dimensions

| Length | 1910 mm |

| Depth | 1720 mm |

Manipulator characteristics (308)

| Dimension (l x w x h) | 720 x 620 x 1400 mm |

| Arm travel | 690 mm |

| Load capacity | 10 kg |

| Storage area | 240 x 135 mm |

Robotic cell

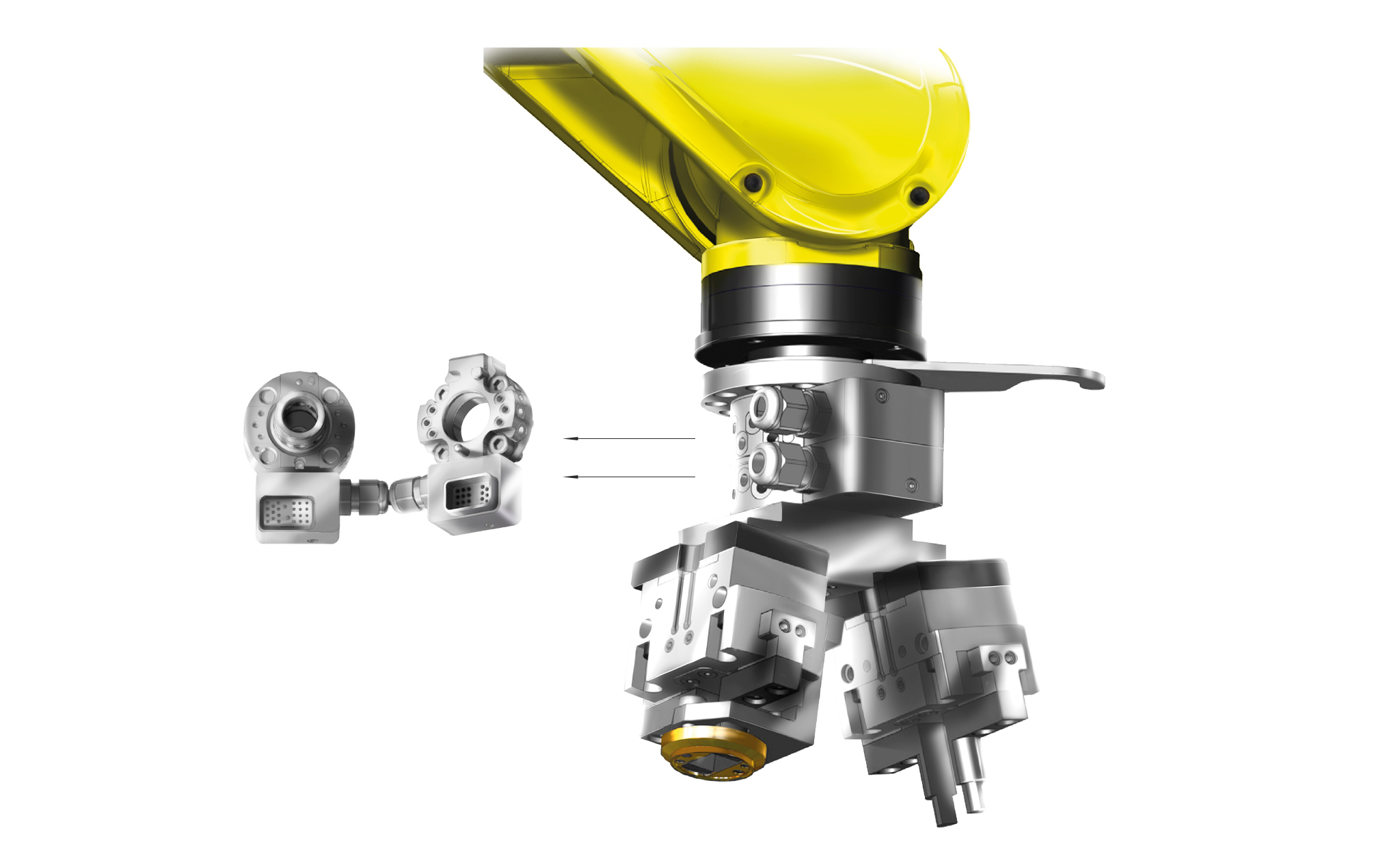

Integrating a poly-articulated robot in a machine facilitates the automation of blank loading and the unloading of machined workpieces on the specified storage racks. The handling of pre-assembled workpieces is also taken into account in the specially designed fixtures.

The robot offers maximum flexibility. It handles both workpieces and pallets equally well, guaranteeing excellent positioning accuracy and handling of workpieces.

508MT2 machine and robot dimensions

| Length | 3192 mm |

| Depth | 2405 mm |

Robot cell characteristics

| Dimension (l x w x h) | 1320 x 770 x 2160 mm |

| Weight | 650 kg |

| Supply voltage | 400 V AC |

| Pneumatic | 6 bar |

| Compatible with Willemin-Macodel machine series | 30 / 40 / 50 / 70 |

308S2 machine and robot dimensions

| Length | 2376 mm |

| Depth | 1782 mm |

Workpiece and fixture storage

| Capacity | Up to 6 drawers in A3 format |

| Load per drawer | 20 kg |

| Drawer actuation | Opening and closing of drawers by the robot |

Robotic cell for one machine

Robot cell for a plurality of machines

FLEXIBLE CELL

The flexible production cell is based on multiple production machines linked by a robotized system and an IT system, enabling the automated production of different types of workpieces, in variable quantities. The cell also enables other functions such as geometric acquisition of blank workpieces, monitoring of finished parts, cleaning/drying of machined parts, laser marking, etc.

This means the robotized system can not only feed the workpieces to the machines but also control automatic set-up changeovers. The flexible cell is designed to handle the production orders sequentially (in consecutive order). As such, there is only ever one production order, and therefore only one type of workpiece, being processed at a time. This simplifies the management model.

POSSIBLE FUNCTIONS

- Flexible machining system (FMS)

- Automatic loading of fixtures and workpieces into the machines

- Complete workpiece machining

- Deburring

- Cleaning and drying

- Measuring the workpiece on the 3D CMM machine

- Identifying and laser-marking the workpiece

- Placing the finished part in the storage system

EXAMPLE OF FLEXIBLE CELL

Advantages and flexibility of the robotization

Innovative functions and flexible application of robotization

One of Willemin-Macodel’s strengths is the ability to provide solutions adapted to the morphology of the workpieces and the operating range.

- 4.0 intelligent automation and functions

- Workpiece and fixture transfer, standalone solution

- High operating autonomy

- Increased production rate

- Flexible solution

- Compact model

The collaborative robot

a new way to automate your process

Why choose a collaborative robot?

- Simplified programming

- Robot can be moved by holding the robotic arm in your hand

- Modern touchscreen tablet and ability to add applications

- Numerous peripherals (electric grippers, vacuum)

- Easy cart positioning in front of the machine

a custom-designed automation solution.

Unlike robotic cells, a collaborative robot is not located in a closed cell, and is distinguished by its ease of use.

With the help of detection sensors, it is able to recognize any obstacle and avoid potential collisions.

- Able to accommodate a format of 6 A4 pallets.

- Wheels equipped with fixed feet to stabilize the structure.

- Equipped with laser scanner for safety.

- Balanced assembly mass to guarantee stability when extending the robot arm.

- WM customization possible (brackets for robot controller integration, cover plates sheets and oil collection plates).

Some technical features.

For further information, please contact the WM Technical Office.

- FANUC CRX 10iA

- Wrist load capacity: 10 kg

- Repeatability (mm): ± 0.04

- Radius: 1249 mm

Workpiece storage

For increased autonomy, the poly-articulated robot rationally manages the storage of blank and machined workpieces, generally in concurrent operation time.

- Storage of machined workpieces in pallets, cups, baskets or a conveyor

Workpiece storage defined by Willemin-Macodel or reuse of customer storage

Storage capacity optimisation

Clamping changeover with GPS70 interface

Interchangeable pallet for different production types

Single unit production and identification of finished part cups

Production in batches stored in a single finished part cup

Solution finder

To bring Willemin-Macodel's expertise to your next machining project, tell us about it by answering these questions.

Let's go!TECHNICAL SUPPORT

We offer a personalized service – from the initial feasibility studies to supporting your machining centre over its life cycle.

India

Willemin-Macodel (India) Private Limited

Plot No. 204-A , 2nd Floor

Antriksh Thakur House

Marol Makwana Road

Marol Naka, Andheri East

IN- 400 059 Mumbai

+91 97 4513 2535

sales.india@willemin-macodel.com

Israel

DIAMOND TECHNOLOGY C.N.C MACHINES LTD

Japan

Eurotechno Inc.

Mikawaya Bldg. 2F

5-20-10 Ogikubo, Suginami-Ku

JP-TOKYO 167-0051

+81.3.3391.1311 +81.3.3391.1310 www.eurotechno.co.jp

Malaysia

Willemin-Macodel SA

Singapore

Willemin-Macodel SA

China

Willemin-Macodel Int. Trading

A2, 1st Floor, No.1 Building

No. 526 Fu Te Dong San Road

Waigaoqiao Pilot Free Trade Zone

Pudong District

CN-200131 Shanghai, P. R. C

+86 21 6208 91 91 +86 21 6208 0599

Hong Kong

Willemin-Macodel Int. Trading

A2, 1st Floor, No.1 Building

No. 526 Fu Te Dong San Road

Waigaoqiao Pilot Free Trade Zone

Pudong District

CN-200131 Shanghai, P. R. C

+86 21 6208 9 1 9 1 +86 21 6208 0599

Taiwan

Willemin-Macodel SA

Thailand

Willemin-Macodel SA

Turkey

Willemin-Macodel SA

South Korea

Willemin-Macodel SA

Vietnam

Willemin-Macodel SA

Austria

H. SUKOPP

Belgium Flanders area

Willemin-Macodel SA

Czech Rep.

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 +41 32 426 55 30

sales@willemin-macodel.com

Denmark

Willemin-Macodel SA

Slovakia

Willemin-Macodel SA

Finland

Willemin-Macodel SA

Norway

Willemin-Macodel SA

Germany

Willemin-Macodel GmbH

Take-Off GewerbePark 4

D-78579 Neuhausen o. E.

+49 (0) 7467 91 05 140 +49 (0) 7467 91 05 148

service.deutschland@willemin-macodel.com

Italy

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 +41 32 426 55 30

sales@willemin-macodel.com

Ireland

Willemin-Macodel Limited

618 Harbour Point Business Park

Little Island

Co. Cork

T45 FD21

+353 21 201 02 33

service.ireland@willemin-macodel.com

Netherlands

Willemin-Macodel SA

Poland

Willemin-Macodel SA

Portugal

Willemin-Macodel SA

Ukrain

Willemin-Macodel SA

United Kingdom

Willemin-Macodel SA

Spain

Willemin-Macodel SA

Sweden

Willemin-Macodel SA

Switzerland

Willemin-Macodel SA

United States of America

Willemin-Macodel Inc.

Mexico

Willemin-Macodel Inc.

Canada

Willemin-Macodel Inc.

Brazil

DYNAMACH

Maquinas e Equipamentos

Rua Correia da Câmara 422

Sao Paulo SP 03268-160 - Brasil

+55 (11) 2143-5758 +55 (11) 2143-6163 www.dynamach.com.br

vendas@dynamach.com.br

Indonesia

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 www.willemin-macodel.com

sales@willemin-macodel.com

Luxembourg

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 www.willemin-macodel.com

sales@willemin-macodel.com

Emirats Arabes Unis

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 www.willemin-macodel.com

sales@willemin-macodel.com

Others

Willemin-Macodel SA

Route de la Communance 59

CH-2800 Delémont

+41 32 427 03 03 www.willemin-macodel.com

sales@willemin-macodel.com

solution finder

solution finder